Binh Le, a third-year TUSPM student from Allentown, PA, has always been interested in the medical field. He studied biology as an undergraduate at Temple University and was particularly interested in orthopedics and dermatology.

This led him to podiatry, as he says it “happened to combine both of them, which I really liked.”

As a student at TUSPM, he excelled at understanding bones and muscles, but he struggled somewhat when it came to systems like nerves and blood vessels. This inspired him to start a new project at the end of his first year to help other first-year students in the same boat.

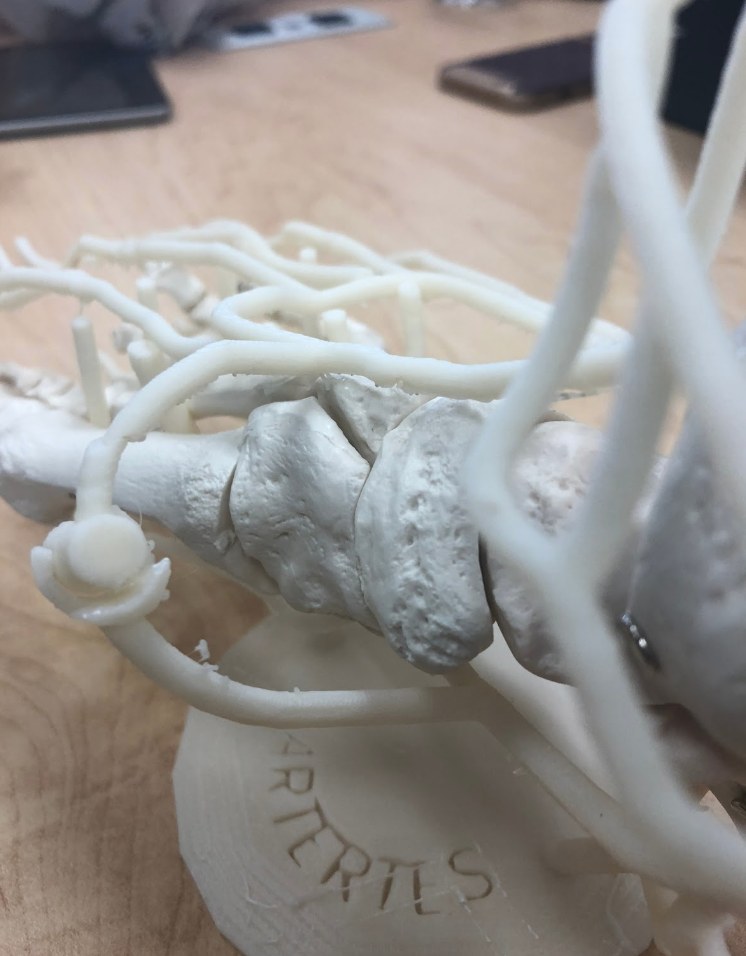

“I figured, what could I do to make it easier on the newer incoming students? So I decided to make a 3D model of [arteries] which will help you visualize it a lot better because there’s not that many out there right now.”

He has been using the LulzBot Taz 6 3D printer in the Krausz library to try and create models of foot arteries. These can either stand alone or be combined with existing bone models of feet to help students better understand and visualize the system.

Prior to this project, Le did not have much experience with 3D printing. He always thought it was interesting, but did not have access to a printer until TUSPM got one in 2018. Even though he lacked experience, he says getting started was not that difficult.

“It’s actually not that bad, especially cause YouTube has a lot of videos out there on it, and there’s this one software called TinkerCAD. They make it super easy in the beginning, but then when I moved on to the more advanced software for my final model it got really hard, hard enough to the point where I still don’t know how to fully use it. But the beginning part is simple.”

Le says he has printed other objects on the printer before, such as “iPad stands and measuring cups, just random items to test if the printer was usable.” However, this is the first 3D printing project he designed himself.

So far, he has completed the 3D modelling, which is done on the computer software. Now, he has to print out the actual physical objects on the printer. There have been some issues with breakage, but he hopes to successfully complete the project before he graduates.

“The printing is where all the troubles come because when you print it out in real life, it might come out right, it might not. So we have to do some adjustments.”

In addition to aiding first-year students in their studies, he also hopes the project will inspire others to start their own projects.

“Honestly I just want to inspire someone else under me to make their own project, because I only have time to do one. If someone else could get on the nerves, that would be great, or if someone else could work on bones, that would be great, too.”

While he’s currently the only one working on the project, he says he would be happy to have people who are interested get involved as well.